The waterproof test artificially recreates the action of violent storms in the so-called rain chamber in order to certify that there is no water entering the pannier in any weather conditions.

- Models

- Configurator

- Shop

- News

- Racing

- DWP 2026

International website

Change

International website

Change

Discover about events and rallies organized by Ducati and the Ducati Official Clubs.

Discover more

The online shop has a whole new look. Our style is the same as always. Buy now!

Click and discover!

When you choose a Ducati Approved bike, you can be sure that Ducati is always by your side.

Discover moreFrom the first sketches to the finished object, it can take 12 months of hard work to obtain a new Ducati Performance side pannier.

A process that is a journey in itself! Discover all the passion for quality, design and functionality that inspired the perfect travelling accessory.

The next step is 3D printing and full prototyping. The prototype is then mounted on the bike to assess volumes, fastening systems and aesthetic aspects.

This is when the intense testing phase starts.

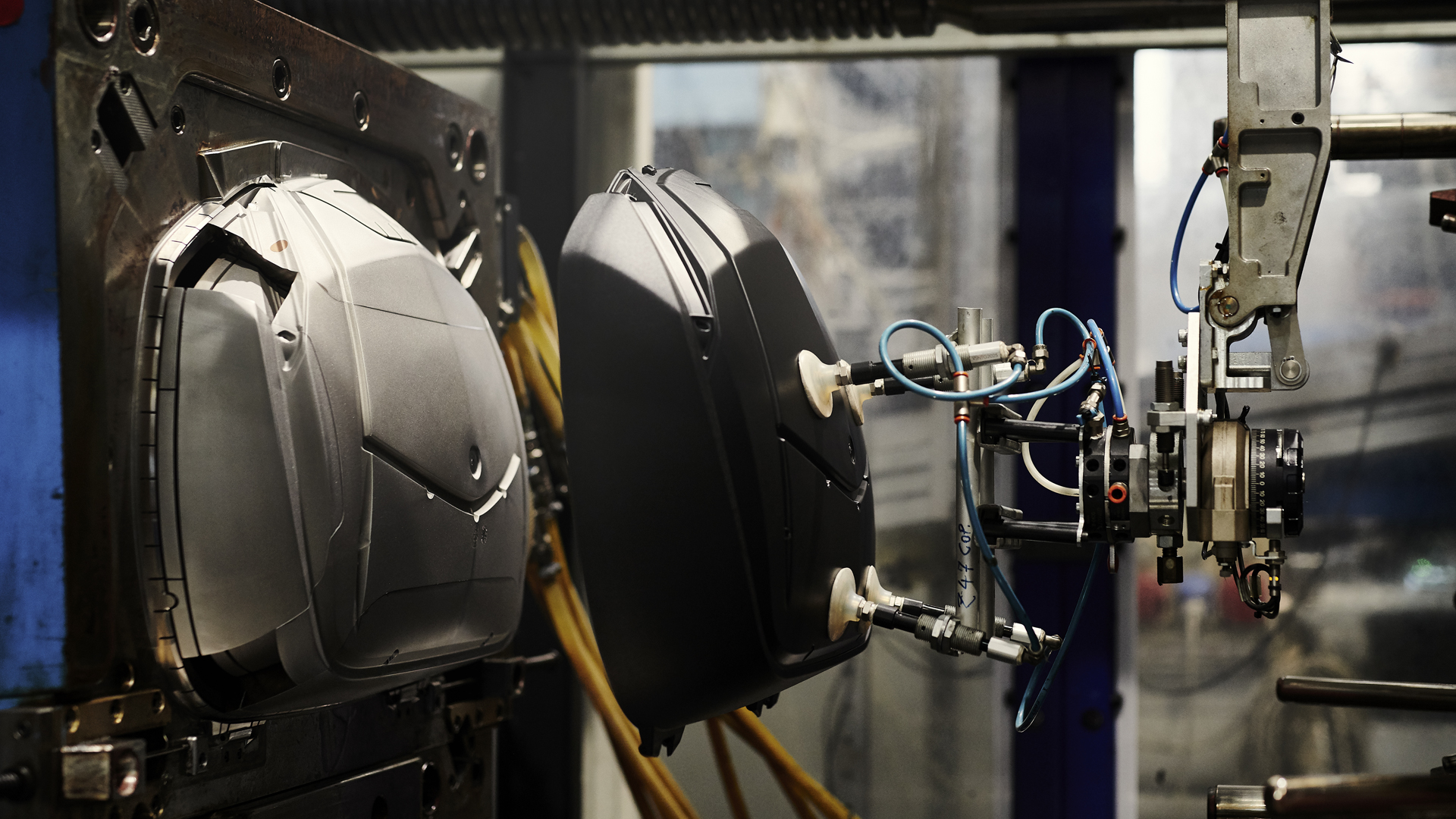

The production phase of the panniers, where the supplier provides its fundamental know-how, can take several months to complete. Consider that just the production of a single steel mould using numerical control milling cutters (for each pannier several are required) can take several months.

Once the moulds have been completed the actual production can start, the output being constantly monitored through inspections of the quality of individual parts.

After the final finishing touches, graphics and logos, the pannier is ready for distribution to the Ducati Dealers.