Ducati Corse |D |air® C2 - Racing suit with airbag system

The Ducati Corse |D|air® C2 riding suit made by Dainese in the exclusive Ducati Corse livery is equipped with an integrated airbag that, in synergy...

The Ducati Corse |D|air® C2 riding suit made by Dainese in the exclusive Ducati Corse livery is equipped with an integrated airbag that, in synergy with the existing protections in the professional suit, covers the shoulders, neck, collarbones and upper chest. Made of D-skin 2.0 full-grain cowhide leather, it has been upgraded with a super-ergonomic construction of the arms and knees, equipped with steel plates integrated directly into the leather and interchangeable sliders. CE-certified, it is the ideal garment for the track thanks to an integrated electronic system that allows the rider to download and verify key performance data like lean angle and speed.

- Biaxial elastic for improved movement and comfort

- Micro-stretch inserts

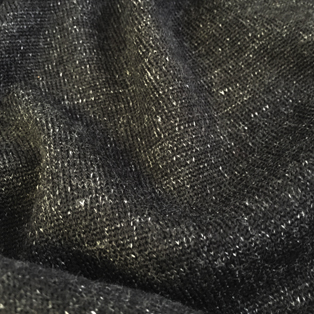

- D-Skin cowhide 2.0

- S1 fabric

- Detachable Nanofeel® lining with 3D-Bubble inserts

- Back protector included

- Localised perforation

- Leather suit bag included

- Three accelerometers

- ECU

- GPS antenna

- Gas generator

- Switching on through the two ON/OFF buttons neck closing

- User interface (LED on right arm)

- Battery range: 8 hours in constant operating conditions

- The D-air® system weights just 650 grams

- Integrated airbag protecting shoulders area (4 litres)

- Online configurator: www.ducatisumisura.com

- In thermoformed composite material, pursuant to EN 1621.1

- Aerodynamic hump

- Preformed steel inserts

- Pro Shape soft protectors, certified according to EN 1621.1

- Ready for back protector certified according to EN 1621.2 – Liv. 1

- D-air® Racing airbag system

- Slider (981033275; 981033276)

- Elbow slider RSS (Replaceable Slider System 981043024)

- CE-marked product, certified according to Regulation (EU) 2016/425 and standard EN 17092-3:2020, Cl. AA

- Track racing use only. To order a SuMisura suit, contact your Ducati dealer.

A material traditionally used in motorcycling clothing that offers a good level of breathability and guarantees increased abrasion resistance. It is a product that, starting from different bases, requires a complex series of manufacturing processes to ensure constant standards in terms of aesthetics and safety. The variation in thickness has a bearing on the perception of softness and resistance to tearing and abrasion. A thinner leather is more comfortable but is used for less technical products because it is less resistant. A thicker leather is more rigid but more resistant to tearing and abrasion. The characteristics also vary according to which part of the leather is used to produce the article.

- Kangaroo leather

-

Glossy finished kangaroo leather (thickness mm 0.9 +/- 0.1), it stands out for excellent tear and abrasion resistance. Among the materials currently in use for racing suits, kangaroo leather stands out for the best mechanical resistance to lightness ratio.

The leather is 0.9 mm (1/32”) thick, making it 25% thinner than cowhide for motorcycle sport use. The same is obviously true for its weight:

One square meter of kangaroo leather weighs just 600 grams (1.32 lbs) and resists to abrasion for 5 seconds

Pros > Cons• Excellent tear and abrasion resistance > high protection in case of falls

• Reduced leather thickness > lighter suit > better comfort, especially in case of prolonged use

• Reduced leather thickness > superior fit > the suit better accommodates the racer’s movement

- D-Skin 2.0

-

Top-quality full-grain cowhide

• Better mechanical performance with respect to traditional cowhide (+60% tensile strength and +80% tear resistance)

• Treated with resins and silicon wax

• Thickness mm 1.2 +/- 0.1

Pros > ConsExtreme abrasion resistance, tear resistance and tensile strength > extreme protection in case of falls/skidding

• Very soft > extremely pleasant to the touch

• Excellent wearability > excellent fit and adaptability to movements while riding

- Tutu

-

Good quality cowhide

• Good mechanical performance

• Water-proof treatment

• Soft finish

• Thickness mm 1.2 +/- 0.1

Pros > Cons• High abrasion resistance, tear resistance and tensile strength > high protection in case of falls/skidding

• Soft > pleasant to the touch

• Good wearability > good riding comfort

- Dorset

-

• Barrel-dyed cowhide with soft retanning

Pros > Cons• Great softness > extremely pleasant to the touch

• Good mechanical performance > good protection in case of a fall

• Excellent fit > excellent adaptability to movement during riding

- New Nappalan

-

Soft cowhide of East Indian Water Buffalo for urban garments

• Thickness 0.9 +/- 0.1 mm

Pros > Cons• Good abrasion resistance, tear resistance and tensile strength > good protection in case of falls/skidding

• Riding comfort

- Buffalo leather

-

Buffalo leather is used in motorcycle apparel thanks to its durability, flexibility and appearance.

Thickness 0,9 +/- 0,1 mm.

The leather is barrel-dyed and then slightly sprayed.

This maintains the natural characteristics of the leather and gives the garment a worn appearance in a short time, thanks to the slight contrast between the black barrel and the sprayed one.

Pros > ConsTough and durable > good abrasion resistance, tear resistance and tensile strength > good protection in case of falls/ skidding

• Soft and flexible > comfortable and pleasant to the touch

• Particular texture and appearance > pleasant touch & feel

Excluding sports use, the use of fabric in motorcycle clothing is increasing rapidly. Thanks to a huge range of materials and technical solutions, products of different weight, volume and technicality can be produced, all designed for specific types of bike usage or for very different climates at prices that are more contained than for similar leather pieces.

- Cordura® Comfort

-

• Stretch technical fabric made of high-tenacity 6.6 Nylon in the warp and stretch 6.6 Nylon in the weft

• Nanotechnology-based finish is used to obtain non-iron, water and oil-repellent fabric

Pros > Cons• Excellent tear and abrasion resistance > great protection in case of falls/skidding

• Excellent wearability > excellent riding comfort

• Good thermal insulation

• Water- and oil-repellent even after washing

• Ironing not needed

- Polyester

-

• Excellent tenacity, high abrasion, wrinkle and heat resistance, high resilience, minimal moisture regain and good resistance to chemical and physical agents. Due to all of these features, polyester is used either pure or combined with other natural, man-made or synthetic fibers.

• More specifically, the polyester used in Ducati summer clothing items has an abrasion resistance of 450 cycles. Weight makes garments less prone to ballooning up at high speeds. A double polyurethane coating on the inside provides wind resistance, breathability and good water repellent properties.

Pros > Cons• Excellent tenacity and high resilience > dimensional stability (no shrinking)

• Good abrasion resistance > 450 cycles (in accordance with UNIEN 388/2004) and a weight of 200 g/sq m > good protection in the event of a fall or skid

• High wrinkle and heat resistance > no wrinkling > great wear and abrasion resistance

• Does not absorb moisture > excellent water and dirt proofing

• Good resistance to chemical and physical agents > excellent durability

• Fabric weight > limited ballooning up even at high speeds > greater comfort

- Polyester twill fabric

-

100% polyester twill fabric, 280 g/m2, abrasion resistant (1450 Martindale cycles, UNI EN ISO 388/2004), waterproofed.

Twill is a type of fabric with a textile weave characterized by an aesthetically pleasing diagonal pattern. This weave grants the fabric softness and good deformability, features that make garments produced with it both comfortable and resistant.

Pros > Cons• Softness of fabric > garments adapt to body movement > excellent ergonomics

• Abrasion resistant > excellent protection in case of falls or slides

• Natural look > eye-pleasing

• Waterproofing > garments will not get soaked in rainy conditions

- Softshell

-

Softshell fabric is a combination of 3 different layers overlapped on one another (polyester outer face, membrane in the middle and micro-fleece inner face). The three layers are pressed together in a laminating machine.

Heat and pressure are applied to the top and bottom layers to bond them together with the breathable membrane in-between.

Each of the three layers fulfills a specific function:

• the tight and elastic weaving of the outer layer provides wind-cutting and water repellent properties.

• the middle layer membrane determines the garment performance: depending on the needs, some products are wind proof and breathable, others waterproof and breathable

• the micro-fleece inner layer keeps the body warm and lends the fabric a soft and pleasant touch.

Pros > Cons• The unique construction of this fabric ensures breathability and keeps out the elements

• Great resilience > In order to fulfill its functions, a Softshell garment must hug the body and flow with its movements > slim fit, great comfort and excellent material performance

• Excellent color fastness and dimensional stability > product features remain unaltered through time

- Cotton

-

• Textile fibre of vegetable origin

• Characterised by good skin friendliness

• Disperses heat quite easily

• Highly hygienic

Pros > Cons• Comfort

• Softness

• Pleasant to the touch

- Cotton Piqué

-

• Mixed fabric

• Due to their higher tension, the bottom warp threads push the weft threads down forming a depression, while the loose threads remain on the surface and create a relief. This creates a quilted effect, enhanced by the softer padding of the weft yarn, also called honeycomb structure.

Pros > Cons• Comfort

• Softness

• Pleasant to the touch

- Jersey cotton

-

• Weft knit fabric

• Slightly elastic structure

• Shaved or honeycomb surface that can be made with any type of fibre

Pros > Cons• Comfort

• Softness

• Pleasant to the touch

- Interlock cotton

-

• Interlock knit cotton fabric

• This fabric is a variant of jersey, but it is easier to cut

• Compact weave double-knit fabric

Pros > Cons• Comfort

• Softness

• Good elasticity (less elastic than ribbed fabric, but much more restraining)

- Cotton and polyester

-

• Polyester is a synthetic fibre which is mixed with polyamide, cotton, etc., in order to make fabrics more restraining and resistant

• The presence of polyester ensures an excellent hold and that the garment will maintain its shape even after numerous washes

• The high percentage of cotton preserves the body thanks to its contact with natural fibre

Pros > Cons• Excellent resistance

• Polyester content ensures excellent shape retention

• Pleasant when it comes in contact with the skin due to the high percentage of cotton

- 100% polyester

-

• Synthetic fibre

• Shiny fabric

• Rough if not properly worked

• Good elasticity and does not wrinkle

• Resistant to mould and bacteria

• Water repellent and does not absorb stains and humidity

• Good breathability if properly worked

Pros > Cons• High tear and abrasion resistance

• Comfort

• Easy garment maintenance (machine washable, non-shrink, crease-resistant)

• Breathability

• Good thermal insulation

• High-speed drying

- Cotton and elastane

-

Elastane fibre grants a series of benefits to the garment, which increase according to the percentage of elastane used:

• soft and flexible

• lightweight

• abrasion-resistant

Pros > Cons• Increased elasticity as % of elastane increases

• Tensile strength proportional to the % of elastane

• High tear resistance

• Resistant to cosmetic oils, sweat, lotions, detergents

• No static electricity problems

• No pilling

- Brushed cotton

-

• Soft and warm fabric

• Even, slightly fuzzy surface

• Particularly warm and yet light, because the fibres raised through brushing retain the air which acts as thermal insulation

Pros > Cons• Lightweight

• Softness

• Pleasant to the touch

• Good thermal insulation

- 100% Polyamide

-

• Technical material, namely a system of innovative and versatile fibres with excellent tear resistance, abrasion resistance and tensile strength

• Made of soft and light fibres characterised by important anti-allergenic properties.

• Excellent moisture wicking properties

Pros > Cons• High tear and abrasion resistance

• High tensile strength

• Ideal for sports and leisure garments

• High-speed drying (three times higher than cotton)

• High breathability

• Extreme comfort

- Fleece

-

• Fleece is a synthetic fabric derived from polyester.

• It is knit using a special technique that makes it bulky and soft. It features many advantages: it is very warm, machine washable, non-shrink, crease-resistant. It is not wind-proof or waterproof.

Pros > Cons• High thermal insulation

• High level of softness

• Inexpensive

• Non-deformable

• Easy garment maintenance (machine washable, non-shrink, crease-resistant)

- Nylon

-

• Its name stems from the merging of the initials of New York (Ny) and London (Lon)

• It can be produced in very fine threads and has an elastic structure which allows it to adapt to the most varied shapes and the most complex and unpredictable movements of the human body

• It is used for all close-fit garments that must follow body movements and for outer coating of anoraks because of its high insulation properties

Pros > Cons• High resistance to wear and tear

• Comfort

• Can be combined with fleece to create warm and waterproof garments

- Neoprene

-

• It looks like a porous rubber

• Lightweight

• Elasticity, resistance to cut and crushing

• Wear and heat resistance

• Inert to chemical agents

Pros > Cons• Inexpensive

• Water resistant

• High tear and abrasion resistance

• Good elasticity

• Breathability

• Warm

• Comfort

• Easy garment maintenance (machine washable, non-shrink, crease-resistant)

- Merino wool

-

• Fibre obtained from Merino sheep

• This type of wool is particularly prized for its fineness, due to the fact that the hair of a merino sheep is thinner than the hair of a common sheep

• Because a merino wool garment is lighter than an ordinary wool garment, it can be worn in warmer seasons too

Pros > Cons• Wear resistance (more resistant that common wool)

• Crease resistance (creases less than common wool)

• Lightweight

- Sheared terry cloth

-

• Great water absorption capacity

• Made with two warps and a weft. The first warp forms the basis of the fabric, the second warp forms the effect which is better known as loop. The shearing consists in cutting the upper part of the loop, thus lending the terry cloth a velvet-like texture

Pros > Cons• Great water absorption capacity

• Extreme softness with velvet effect

• Pleasant to the touch

The linings, whether fixed or detachable, offer an important contribution to the comfort of the garment and therefore to the well-being and safety of the motorcyclist. They are made with technical fabrics that, depending on the use of the garment, cool, warm or help maintain the body’s microclimate.

Membranes are a fundamental functional element for many items in the collection. Whether they are laminated on the outer layer or removable, they are made of high quality materials that offer waterproofness and/or protection from the wind while maintaining great breathability and excellent comfort.

- 3D Bubble

-

Thanks to this special three-dimensional lining, an air chamber forms between the outside and inside of the garment, in order to provide an ideal microclimate.

Pros > Cons• Good inner ventilation > fast drying in warm weather

• Good insulation at mild temperatures > as the outer temperature varies, it is not necessary to add or remove the thermal lining

• Excellent fit > does not require the addition of a further thermal lining, which would modify the garment’s fit

- Nanofeel®

-

• Innovative bacteriostatic polyester lining developed using nanotechnology

• Silver ion nanoparticles added to the yarn during the extrusion process: this process is unlike any ordinary finishing process, since the ions become embedded in the fibre and are evenly distributed inside the yarn

Pros > Cons• Bacteriostatic > more hygienic

• Prevents unpleasant odours > better comfort

• Maximum fabric stability and wash resistance > the product features remain unaltered through time

- Techframe

-

• Inner liner made of high-tenacity polyamide yarns and woven fibres that provide excellent mechanic performance

Pros > Cons• Maximum fabric stability > the product features remain unaltered through time

• High mechanical resistance parameters > compliant with the standards required to obtain the CE certification

- S1 Fabric

-

• Elastomer coated with Polyamide in warp and weft

• Bi-axial elastic properties: the fabric is elasticized in width and length

• Water- and oil-repellent treatment

• 715 g/m2

Pros > ConsHigh mechanical resistance > high abrasion resistance, tear resistance and tensile strength

• Good elasticity > good vertical and horizontal flexibility

• Good wearability > good riding comfort

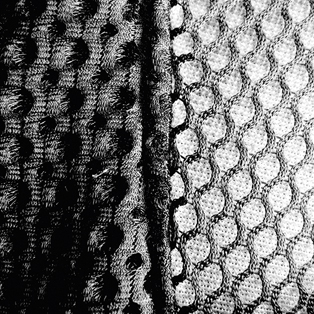

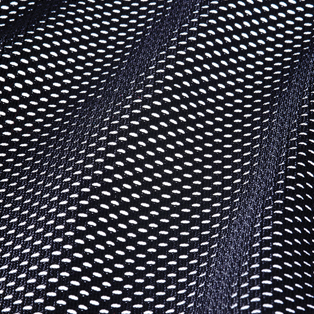

- Mesh

-

• Mesh fabric used for breathable garments ideal for hot and humid climate

Pros > Cons• Fresh > excellent riding comfort

• Breathable > maximum aeration

• Lightweight

- H2OUT®

-

H2OUT® is a special micro-porous waterproof, windproof, breathable membrane, that Spidi created after long term studies and tests in cooperation with big Japanese textile group Toray and OutDry.

The membrane is specific for motorcycling, when water and wind soak through the fabric, and body temperature tends to drop if the right protection is missing. Tested and constantly updated with the use of Tecnorama artificial weather simulator for more than 20 years.

Pros > Cons• Waterproof over 20.000mm H2O

• Breathability over 10.000g/ m2/24h (* A-1 upright cup method JIS L1099 A-1, ISO 2528)

• Water repellency over 80 points (after 20 wash cycles)

• Wind and rainproof > great comfort even in adverse weather conditions

- D-Dry®

-

The hydrophilic membrane applied to D-Dry® fabric, developed by Dainese D-Tec®, has a particular structure that ensures total waterproof combined with an high breathability, thanks to the come out of water vapour produced by the body

Pros > Cons• Waterproof over 10,000 mm H2O

• Breathability

• Windproof > maximum comfort in different weather conditions

- Windout

-

Windout is a wind-proof, breathable membrane designed to protect against the wind-chill effect (i.e. the heat loss perceived by the human body when exposed to the combined effects of low temperatures and wind.

As a matter of fact, the cooling effect of the wind makes the human body feel colder than the actual air temperature).

Made from 120 g/sq m polyamide fabric with water repellent treatment on the outside and breathable, windstopper inner coating.

Pros > Cons• Wind-proof > good comfort in all weather conditions

• Breathability > good aeration

• Water repellent treatment + inner coating > 3.000-mm water column and moisture vapor transport rate of 400 g/ sq m/24 hr (iso uni 4818 part 26).

- Elbow slider RSS 2.0 (Replace-able Slider System)

-

Designed to allow for elbows to slide safely on road pavement.

RSS is made up of:

• A replaceable nylon slider with a special design that facilitates sliding over road surface

• An alluminium plate on the back of the elbow

• Easy-grip area facilitates proper sleeve positioning

• Double screw attachment system for slider replacement

Pros > Cons• Nylon slider. at any angle of the elbow > it adapts to any track and riding style

• Alluminium plate: enhanced protection in the event of a fall

• Easy-grip area: improved fitting and proper positioning of protections

• Double screw attachment

system for slider replacement >quick replacement

- Interchangeable aluminum shoulder plate

-

The aluminum plate in the center of the shoulder protection can also be changed by the end customer by unscrewing the four screws and replacing the damaged plate with a new one, which can be purchased as a spare part.

Pros > Cons• reduced volume > high comfort, attractive look

• high abrasion resistance > extreme protection

• smooth surface for reduced friction prevents dangerous rotations in the event of a fall

• interchangeable plate > greater practicality > less time required for replacement

- Co-Injected Shoulder

-

The co-injected shoulder replaces removable composite protectors

• Comprises a CE-approved protector made through the injection of plastic material over a mesh externally covered in polyurethane

• A pocket for the insertion of the metal plate fastened by rivets on the inside is created inside this structure

• Jointed to the rest of the garment

Pros > Cons• High impact energy absorption and distribution > extreme protection in case of falls/ skidding

• Reduced volume > high comfort, attractive look

• High abrasion resistance > extreme protection

• Since the protector is fixed, it maintains the correct position in the event of a fall

• Smooth surface for reduced friction in the event of a fall

- Metal Inserts

-

Aluminium inserts. May be placed on shoulders and/or knees and/or elbows.

Pros > Cons• High impact energy absorption and distribution > extreme protection in case of falls/skidding

• High abrasion resistance > extreme protection

• Smooth surface for reduced friction prevents dangerous rotations in the event of a fall

- Preformed plastic inserts

-

External PU shoulder protection offer additional abrasion resistance in key impact area.

Ergonomic, dual density plastic inserts.

Pros > Cons• Glossy material > friction control for a stable sliding in case of crash, plus additional impact protection

• Ergonomy > good riding comfort

- Composite Protectors

-

UNI EN 1621.1* certified composite protectors

• A rigid outer plastic shell absorbs and distributes impact energy over the protector’s entire surface thanks to a thin reticulated structure

• The inner part of the protectors is made of high-density expanded polyethylene with high deformation and low memory properties

Pros > Cons• High impact energy absorption and distribution > extreme protection in case of falls/ skidding

• Lightweight and thin > good comfort

- Pro-Shape Protectors

-

EN 1621.1 certified soft protectors*

• Made of an outer layer in polymer with high absorption capacity and remarkable elasticity, bonded to an inner layer of polyethylene foam

• The perforated structure also ensures the correct ventilation of the area

Pros > Cons• High impact energy absorption and distribution > good protection in case of falls/ skidding

• Flexible, lightweight and ergonomic > good riding comfort

• Lightweight > good ventilation

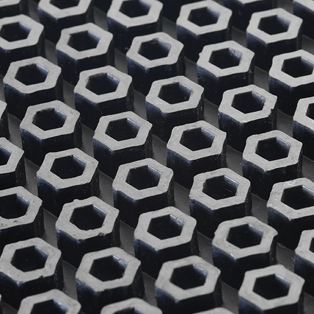

- Pro-Armor Protectors

-

Nitrile rubber protectors are certified to EN 1621.1 – very thin, lightweight and with ergonomic design. Fully perforated construction. Hexagon pattern for superior absorption capacity. The design draws inspiration from the patterns used in nature to create complex structures that offer more protection or more flexibility depending on how their elements are arranged in the space

Pros > Cons• High impact energy absorption and distribution > high protection in case of falls/ skidding

• Hexagon pattern in contact with the body, pre-curved ergonomic shape, great flexibility > high riding comfort

• Lightweight, perforated frame> excellent ventilation

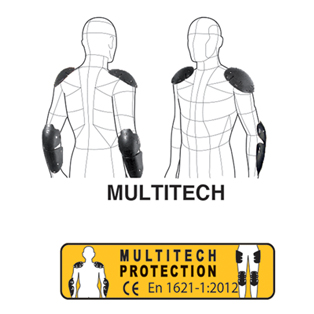

- MultiTech Protectors

-

MultiTech protectors have been designed incorporating the safety and health requirements of certification standards, yet with enhanced comfort, ergonomic and kinematic properties.

Extreme flexibility, low thickness, a soft feel and excellent adaptation to the body, ventilation areas are their key features.

Pros > Cons• EN1621-1 certification, Type A, level 1. Transmitted energy 29.8kN (shoulder) 29.6 kN (elbow) > certified protection

• Total weight of kit is 360 gr > lightweight

• extreme flexibility, low thickness, soft feel and excellent adaptation to the body > great comfort

• ventilation areas > keeps body cool and lets moisture escape > riding comfort

International website

International website

DesertX

DesertX

Diavel

Diavel

XDiavel

XDiavel Hypermotard

Hypermotard

Monster

Monster

Streetfighter

Streetfighter Multistrada

Multistrada Panigale

Panigale

35 kW Bikes

35 kW Bikes Off-Road

Off-Road E-BIKE

E-BIKE

Limited Series

Limited Series