| Engine |

|

|

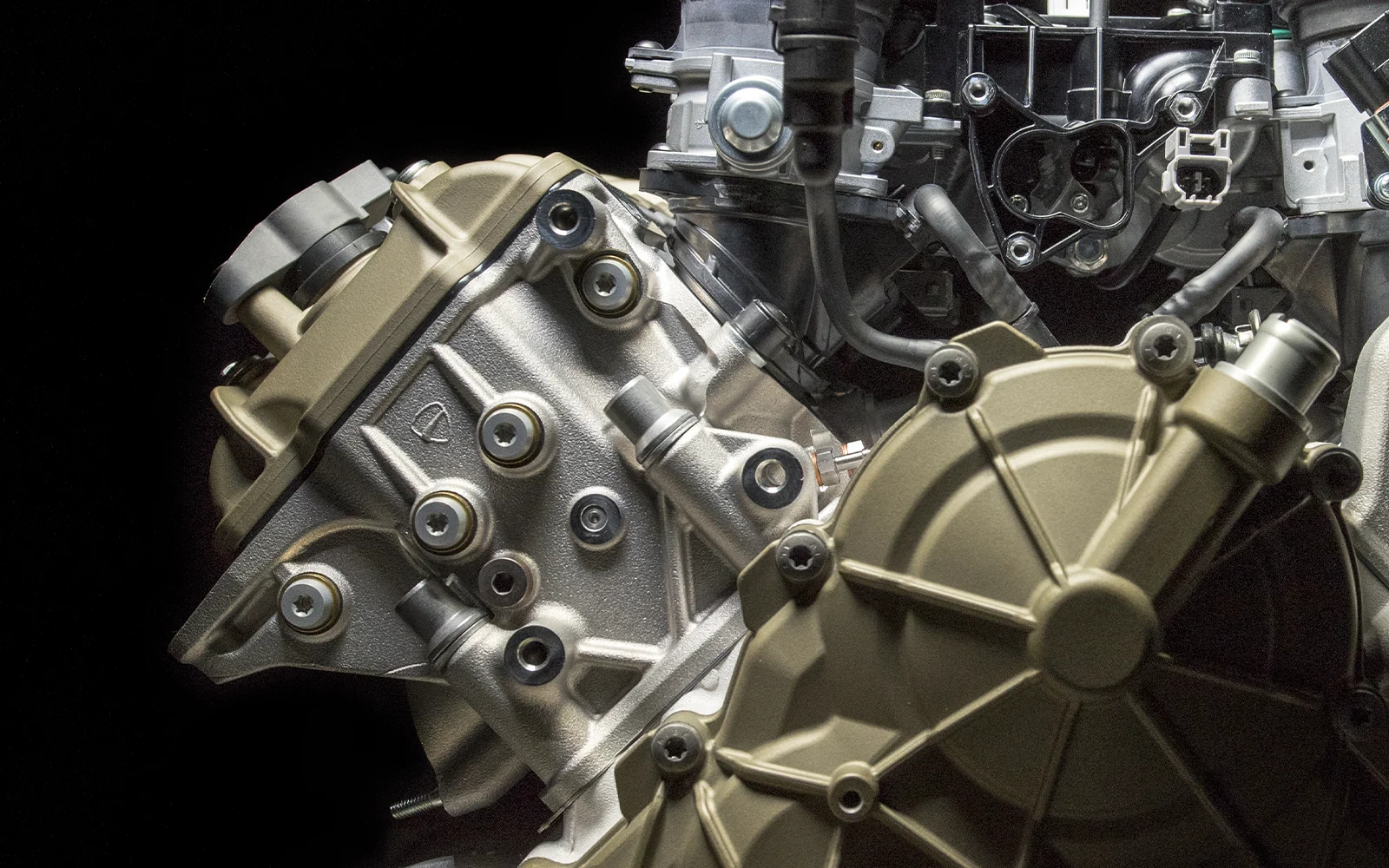

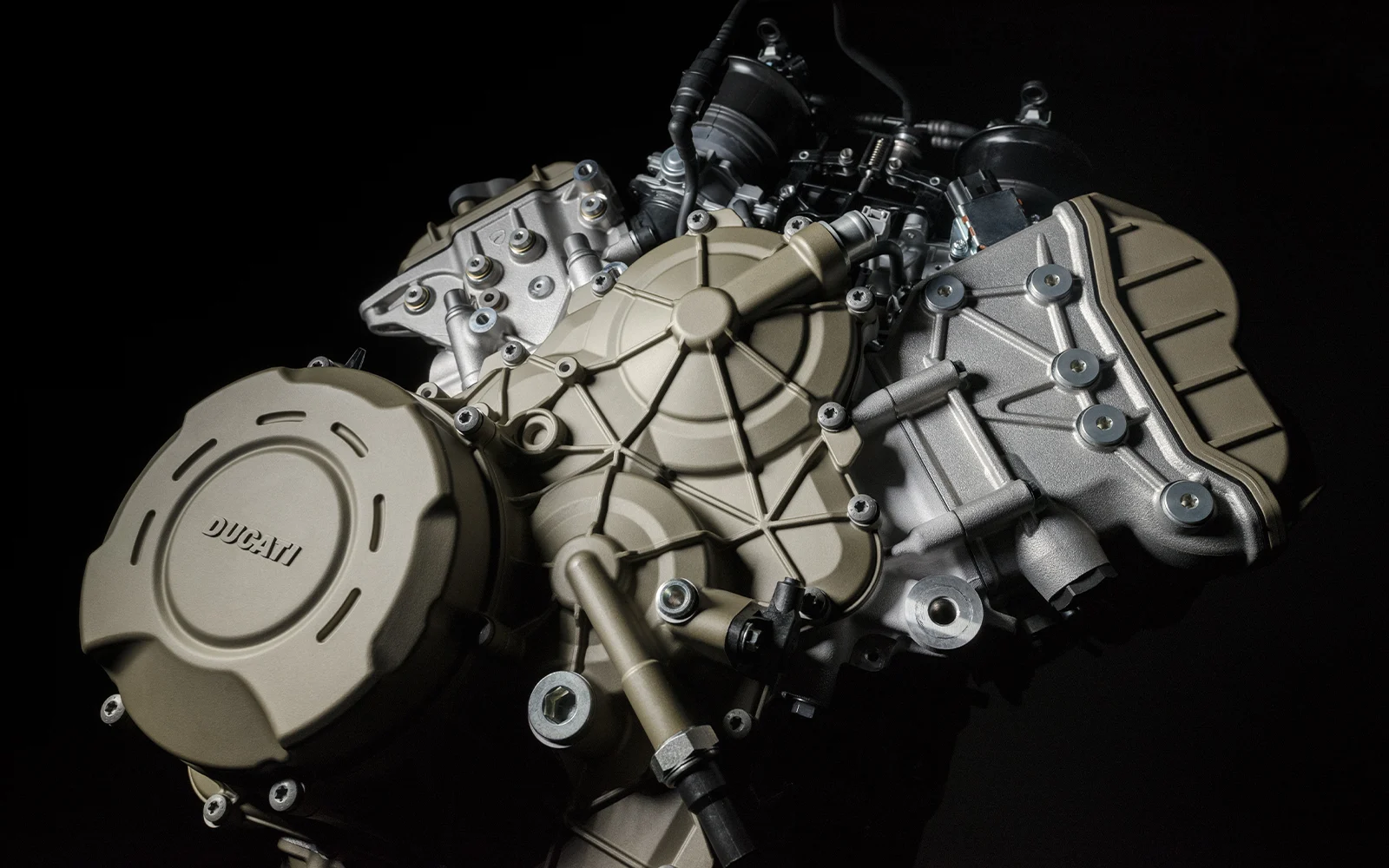

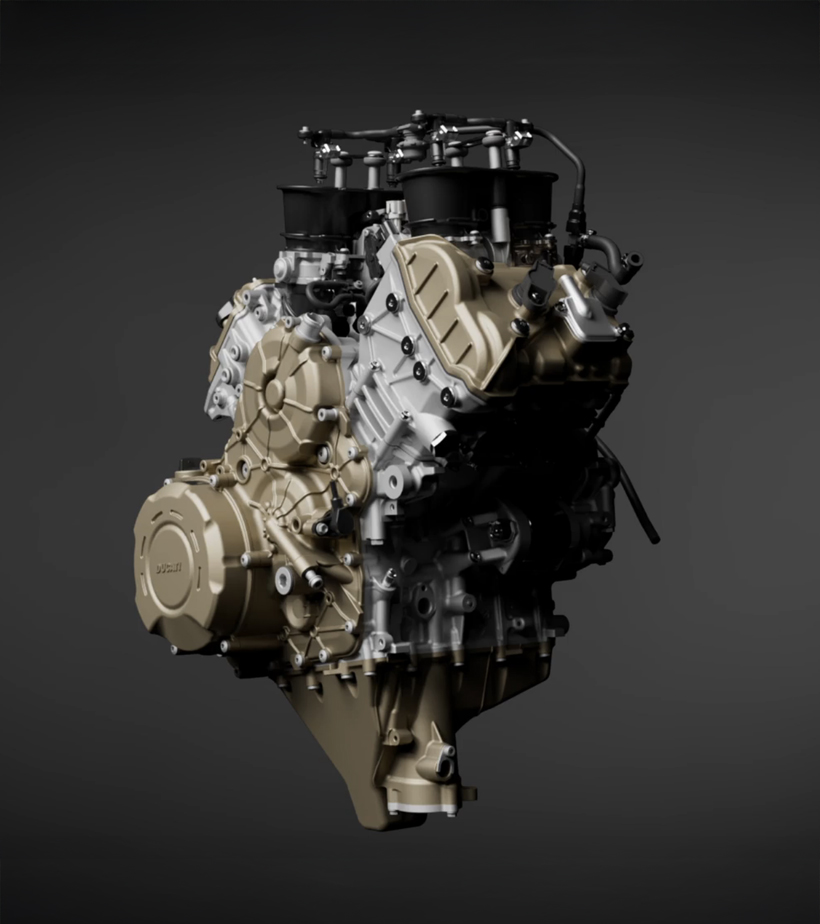

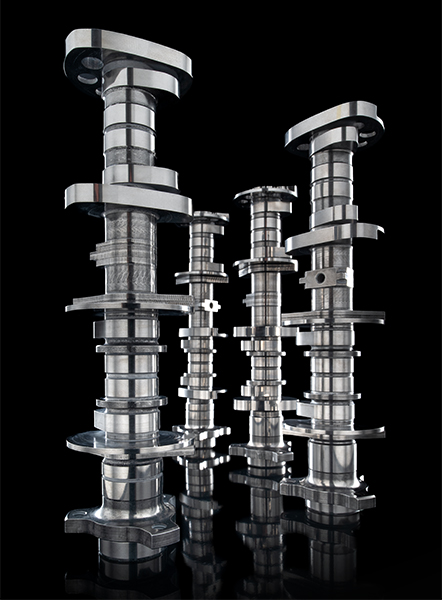

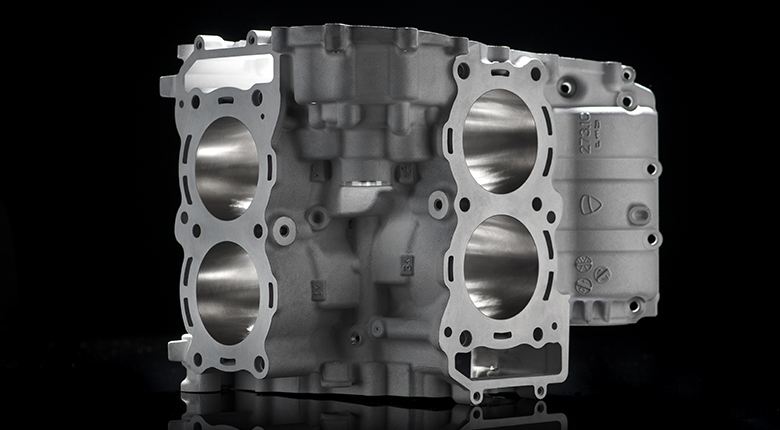

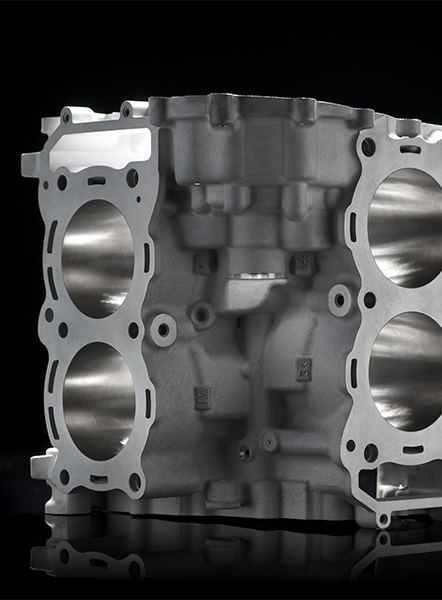

| Type |

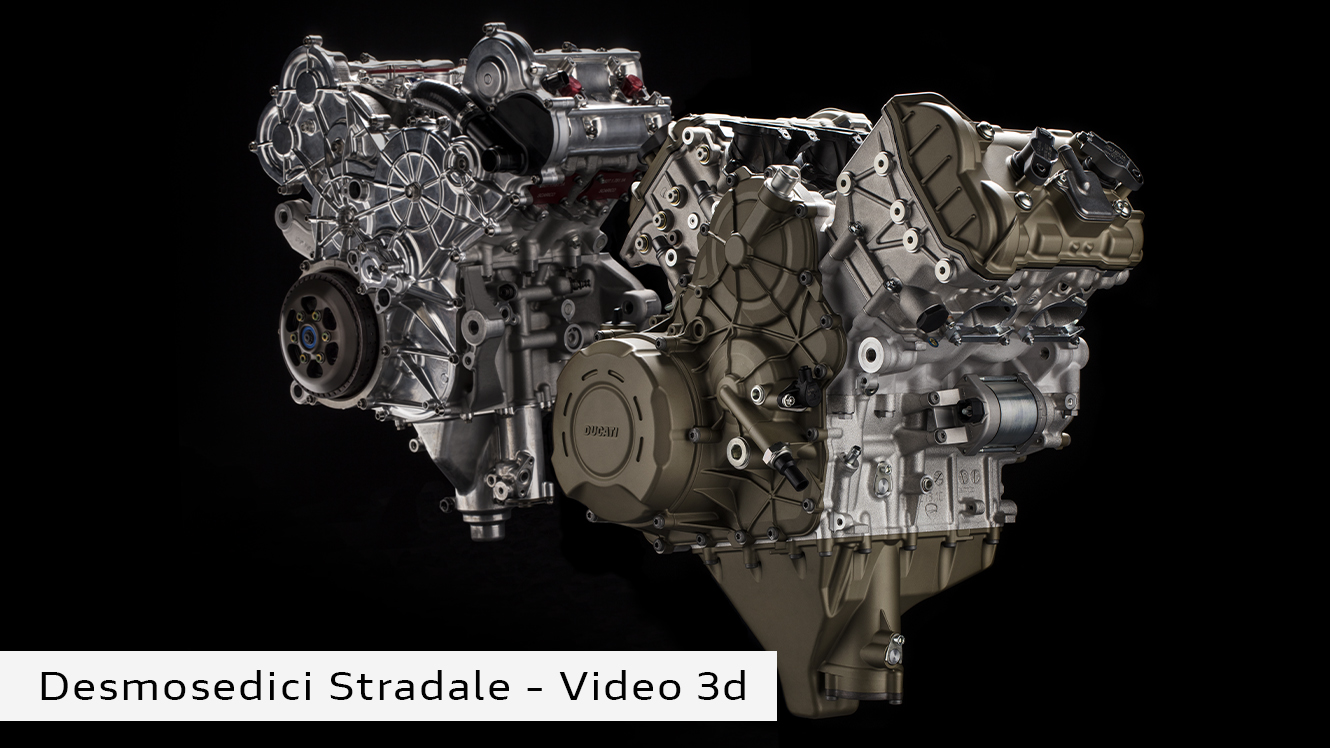

Desmosedici Stradale 90° V4, counter-rotating crankshaft, Desmodromic timing, 4 valves per cylinder, liquid-cooled |

Desmosedici Stradale 90° V4, counter-rotating

crankshaft, Desmodromic timing, 4 valves per

cylinder, liquid-cooled |

| Displacement |

1,103 cc |

1,103 cc |

| Bore x Stroke |

81 x 53.5 mm |

81 x 53.5 mm |

| Compression Ratio |

14.0:1 |

14.0:1 |

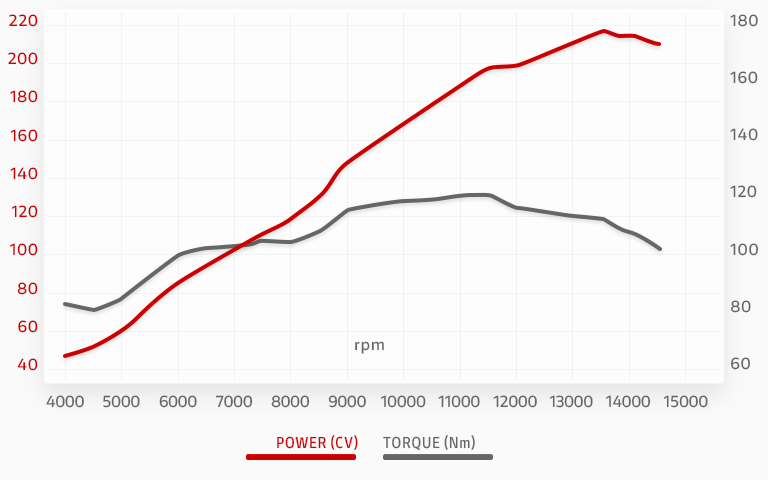

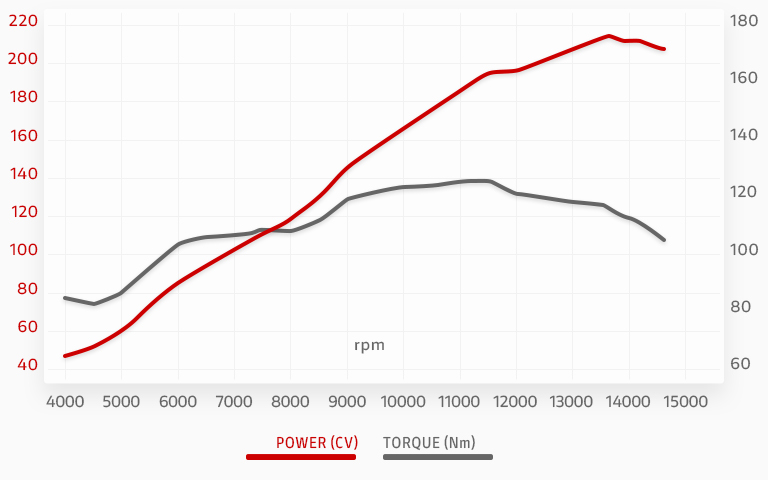

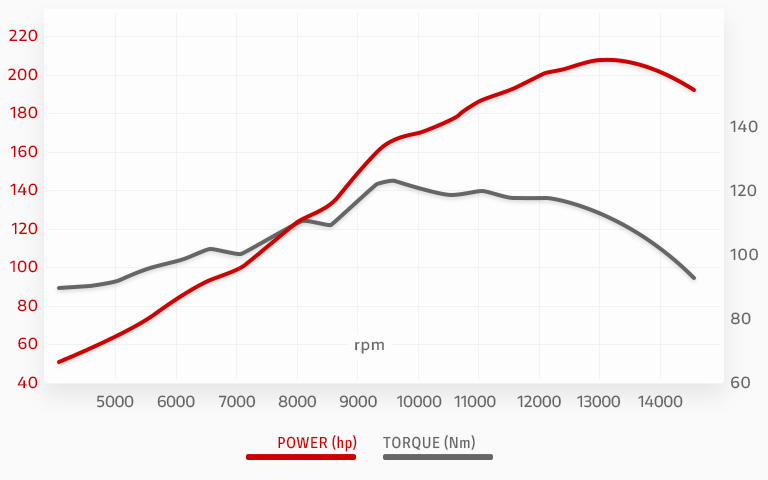

| Power |

158.9 kW (216 hp) @ 13,500 rpm

153.5 kW (209 hp) @ 12,750 rpm (USA/CAN/MEX) |

157.4 kW (214 hp) @ 13,500 rpm

150.7 kW (205 hp) @ 12,650 rpm (USA/CAN/MEX) |

| Torque |

120.9 Nm (89.2 lb-ft) @ 11,250 rpm

121.3 Nm (89.5 lb-ft) @ 11,250 rpm (USA/CAN/MEX) |

120.0 Nm (88.5 lb-ft) @ 11,250 rpm

119.7 Nm (88.3 lb-ft) @ 11,500 rpm (USA/CAN/MEX) |

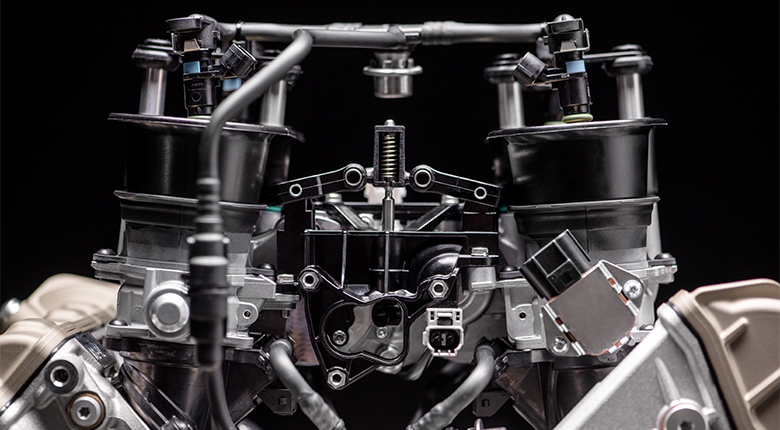

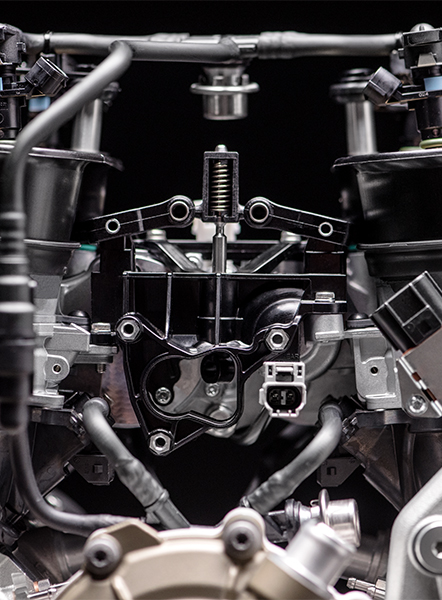

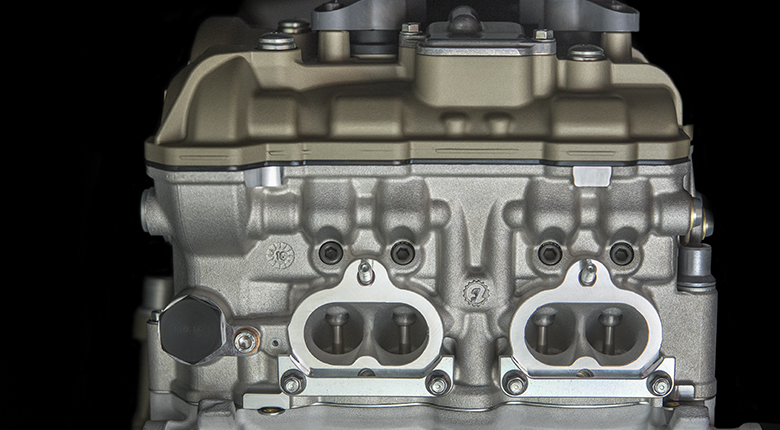

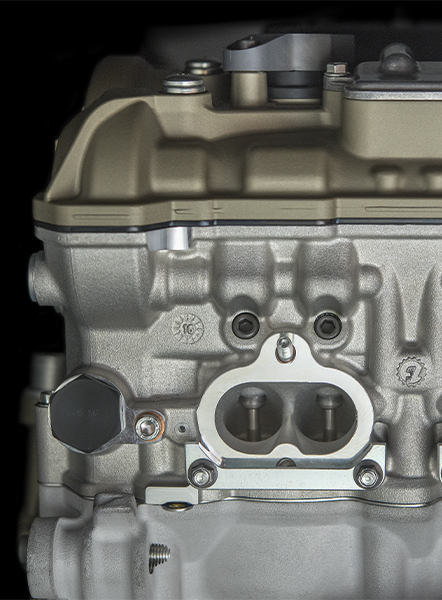

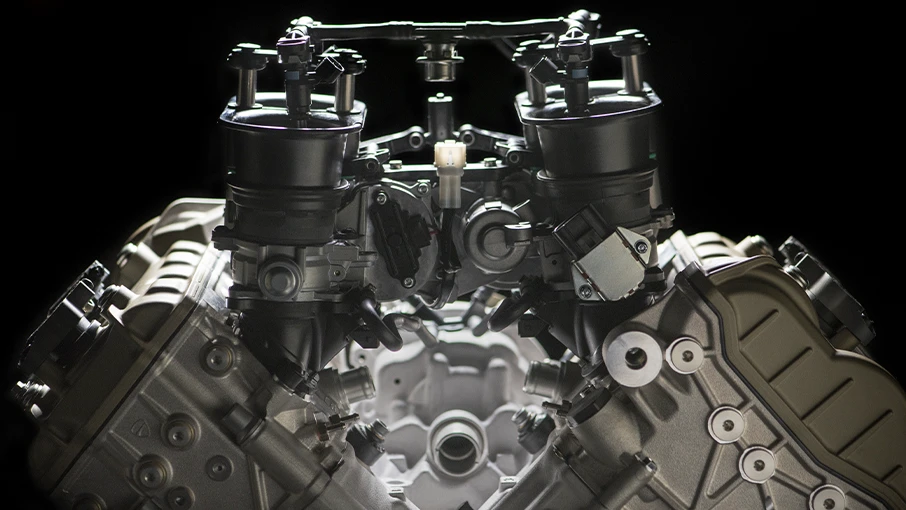

| Fuel Injection |

Electronic fuel injection system. Twin injectors per cylinder. Full ride-by-wire elliptical throttle bodies. Variable length intake system |

Electronic fuel injection system. Twin injectors per cylinder. Full ride-by-wire elliptical throttle bodies. Variable length intake system |

| Exhaust |

4-2-1-2 system, with 2 catalytic converters and 6 lambda probes (Euro 5+ Only)

4-2-1-2 system, with 2 catalytic converters and 4 lambda probes |

4-2-1-2 system |

| Transmission |

|

|

| Gearbox |

6 speed with Ducati Quick Shift (DQS) up/down 2.0 |

6 speed with Ducati Quick Shift (DQS) up/down 2.0 |

| Primary drive |

Straight cut gears; Ratio 1.80:1 |

Straight cut gears; Ratio 1.80:1 |

| Ratio |

1=36/15 2=34/17 3=33/19 4=32/21 5=30/22 6=27/22 |

1=38/14 2=36/17 3=33/19 4=32/21 5=30/22 6=30/24 |

| Final drive |

Chain 520; Front sprocket 16; Rear sprocket 41 |

Chain 520; Front sprocket 15; Rear sprocket 42 |

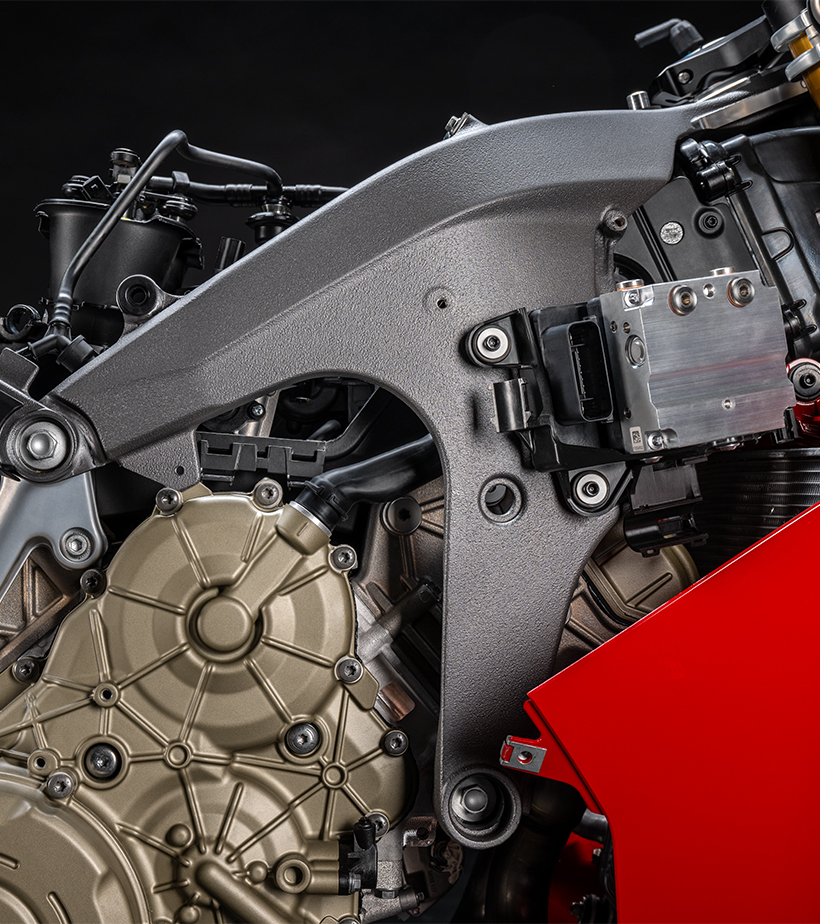

| Clutch |

Hydraulically controlled slipper and self-servo wet multiplate clutch. Self bleeding master cylinder. |

Hydraulically controlled slipper and self-servo wet multiplate clutch. Self bleeding master cylinder. |

| Chassis |

|

|

| Frame |

Aluminum alloy "Front Frame" with optimized stiffnesses |

Aluminum alloy "Front Frame" with optimized stiffnesses |

| Front suspension |

Fully adjustable Showa BPF fork, 43 mm chromed inner tubes |

Fully adjustable Showa BPF fork, 43 mm chromed inner tubes |

| Front Wheel |

5-spokes light alloy 3.50" x 17" |

5-spokes light alloy 3.50" x 17" |

| Front Tyre |

Pirelli Diablo Supercorsa SP-V4 120/70 ZR17 |

Pirelli Diablo Rosso IV Corsa 120/70 ZR17 |

| Rear suspension |

Fully adjustable Sachs unit. Aluminium Hollow Symmetrical Swingarm |

Fully adjustable Sachs unit. Aluminium Hollow Symmetrical Swingarm |

| Rear Wheel |

5-spokes light alloy 6.00” x 17” |

5-spokes light alloy 6.00” x 17” |

| Rear Tyre |

Pirelli Diablo Supercorsa SP-V4 200/60 ZR17 |

Pirelli Diablo Rosso IV Corsa 200/60 ZR17 |

| Wheel Travel (Front/Rear) |

125 mm (4.9 in) - 130 mm (5.1 in) |

125 mm (4.9 in) - 130 mm (5.1 in) |

| Front Brake |

2 x 330 mm semi-floating discs, radially mounted Brembo Monobloc Hypure® 4-piston callipers with Race eCBS. Self bleeding master cylinder. |

2 x 330 mm semi-floating discs, radially mounted Brembo Monobloc Hypure® 4-piston callipers with Race eCBS. Self bleeding master cylinder. |

| Rear Brake |

245 mm disc, 2-piston calliper with Race eCBS |

245 mm disc, 2-piston calliper with Race eCBS |

| Instrumentation |

Digital unit with 6,9" TFT display and Optical Bonding, 1,280 x 480 px resolution |

Digital unit with 6,9" TFT display and Optical Bonding, 1,280 x 480 px resolution, 8:3 aspect ratio |

| Dimensions and Weights |

|

|

| Wet weight no fuel |

191 kg (421 lb) |

191 kg (421 lb) |

| Seat Height |

850 mm (33.5 in) |

845 mm (33.3 in) |

| Wheelbase |

1,485 mm (58.5 in) |

1,496 mm (59 in) |

| Rake |

24° |

24,5° |

| Trail |

98 mm (3.86 in) |

99 mm (3.9) |

| Fuel Tank Capacity |

17 l - 4.49 gallon (US) |

16 l (4.2 US-gallons) |

| Number of Seats |

Single seat / Two seats, depending on country homologation |

Single seat / Two seats, depending on country homologation |

| Equipment |

|

|

| Safety Equipment |

Riding Modes, Power Modes, Race eCBS, Ducati Vehicle Observer (DVO), Ducati Traction Control (DTC) DVO, Ducati Wheelie Control (DWC) DVO, Ducati Slide Control (DSC), Engine Brake Control (EBC), Ducati Brake Light (DBL), Chain guard |

Riding Modes, Power Modes, Race eCBS, Ducati Vehicle Observer (DVO), Ducati Traction Control (DTC) DVO, Ducati Wheelie Control (DWC) DVO, Ducati Slide Control (DSC), Engine Brake Control (EBC), Ducati Brake Light EVO (DBL)*

|

| Standard Equipment |

Ducati Power Launch (DPL) DVO, Ducati Quick Shift (DQS) up/down 2.0, Full LED headlights with Daytime Running Light (DRL), Sachs steering damper, Quick adjustment buttons, Pit Limiter, Auto-off indicators |

Ducati Power Launch (DPL) DVO, Ducati Quick Shift (DQS) up/down 2.0, Full LED headlights with Daytime Running Light (DRL)*, Sachs steering damper, Quick adjustment buttons, Pit Limiter, Auto-off indicators, Coming Home

|

| Ready for |

Ducati Data Logger (DDL), Anti-Theft, Cruise Control, Tyre Pressure Monitoring System (TPMS), USB port*, Ducati Multimedia System (DMS)*, "Turn By Turn" navigator*

*: Please refer to your local dealer for availability |

Ducati Data Logger (DDL), Cruise Control, Tyre Pressure Monitoring System (TPMS), USB port*, Ducati Multimedia System (DMS)*, "Turn By Turn" navigator* |

| Warranty |

|

|

| Warranty |

24 months unlimited mileage |

24 months unlimited mileage |

| Valve Clearance Check |

24,000 km (15,000 miles) |

12 months |

| Annual Service |

12 months |

12,000 km (7,500 miles) / 24 months |

| Oil Service |

12,000 km (7,500 miles) / 24 months |

24,000 km (15,000 miles) |

| Emissions and Consumption |

|

|

| Standard |

Euro 5+ |

Euro 5+ |

| CO2 Emissions |

151 g/km |

165 g/km |

| Consumption |

6,5 l/100 km |

7,1 l/100 km |

| Emission Notes |

Only for countries where Euro 5+ standard applies. |

Only for countries where Euro 5+ standard applies. |

| Notes |

|

|

| Notes |

Bike specifications and equipment may vary from market to market. Please refer to your local dealer for further information |

*: Please refer to your local Dealer for availability

Bike specifications and equipment may vary from market to market. Please refer to your local dealer for further information |

International website

International website

DesertX

DesertX Diavel

Diavel XDiavel

XDiavel

Hypermotard

Hypermotard Monster

Monster Streetfighter

Streetfighter

Multistrada

Multistrada Panigale

Panigale

35 kW Bikes

35 kW Bikes

Off-Road

Off-Road E-BIKE

E-BIKE

Ducati Speciale

Ducati Speciale