- 110,3 hp Power

- 92 Nm Torque

- 209 kg (461 lb) Wet weight no fuel

- Models

- Configurator

- Shop

- News

- Racing

- DWP 2026

International website

Change

International website

Change

Discover about events and rallies organized by Ducati and the Ducati Official Clubs.

Discover more

The online shop has a whole new look. Our style is the same as always. Buy now!

Click and discover!

When you choose a Ducati Approved bike, you can be sure that Ducati is always by your side.

Discover moreThe Ducati Multistrada V4 S has successfully completed the rigorous 100,000 km endurance test conducted by German magazine Motorrad, one of Europe's most authoritative motorcycle publications. Over approximately 1,300 days, the bike faced all kinds of weather and road conditions, crossing Europe and enduring three winters without ever compromising its functionality.

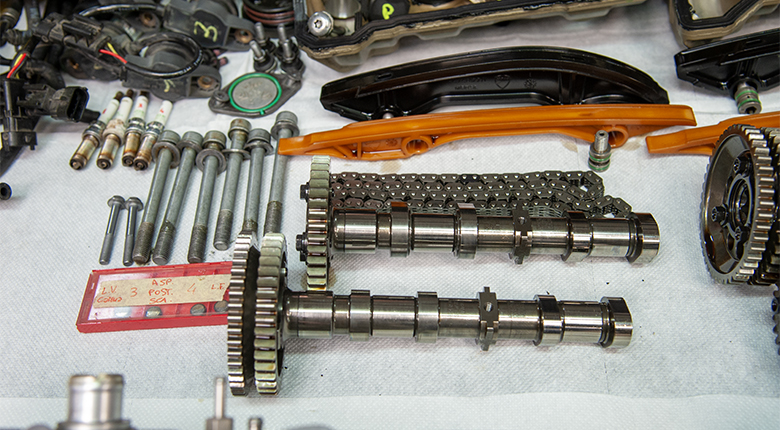

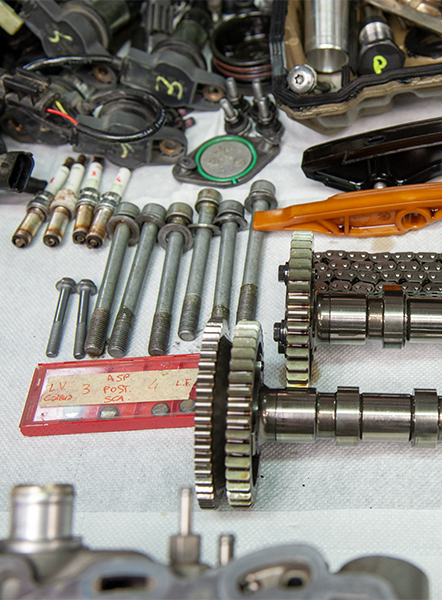

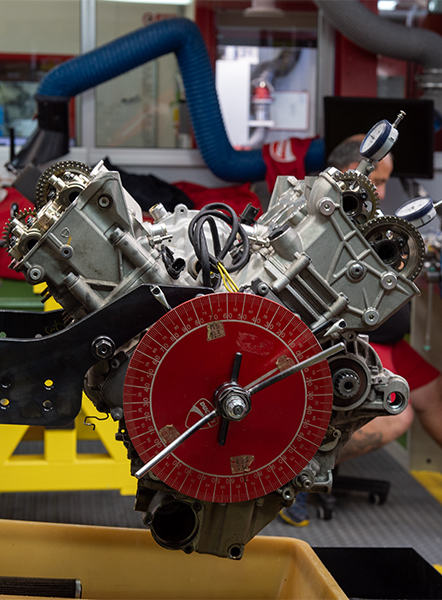

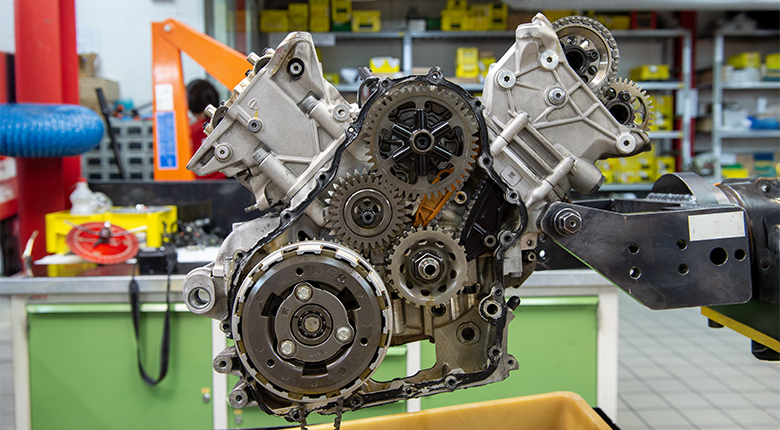

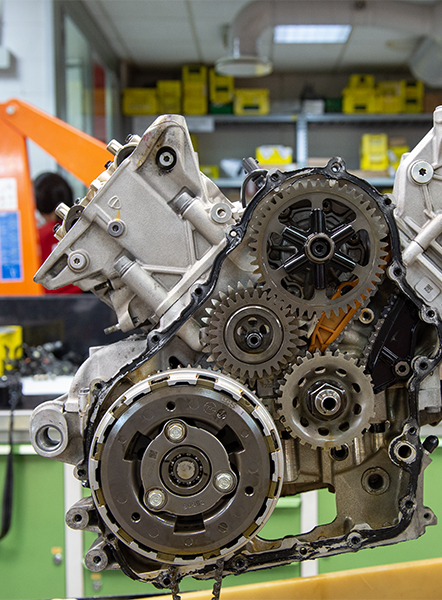

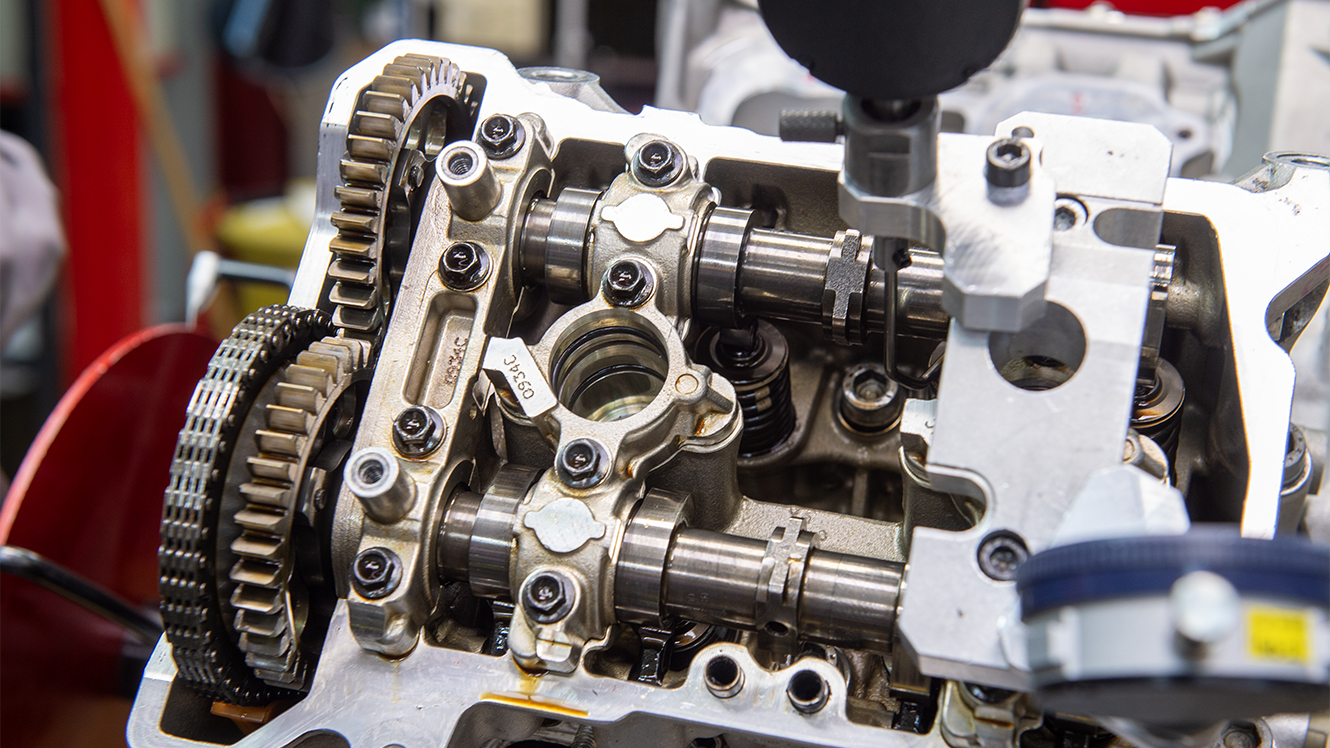

The result is an official certification of reliability that confirms the solidity of the Ducati project and the quality of the V4 Granturismo engine, which at the end of the test showed minimal signs of wear, no loss of compression, and even higher performance than at the start of the test, with almost 6 hp more detected on the test bench.

During the test, the Multistrada faced:

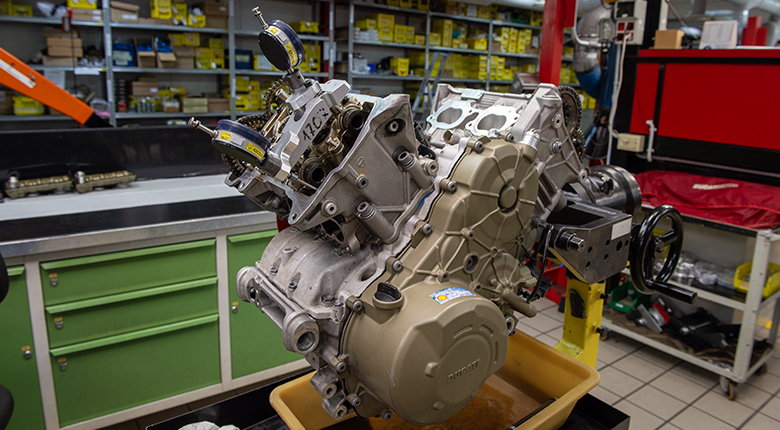

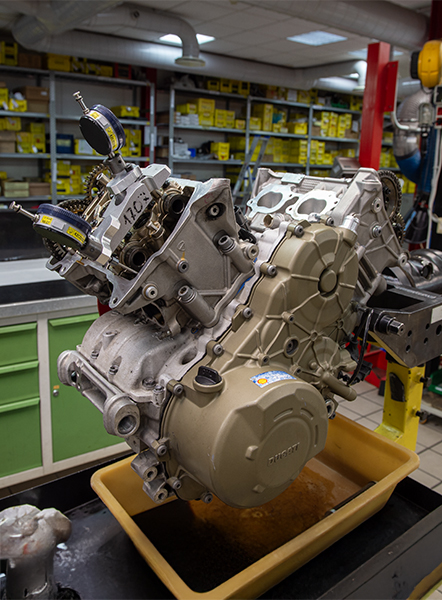

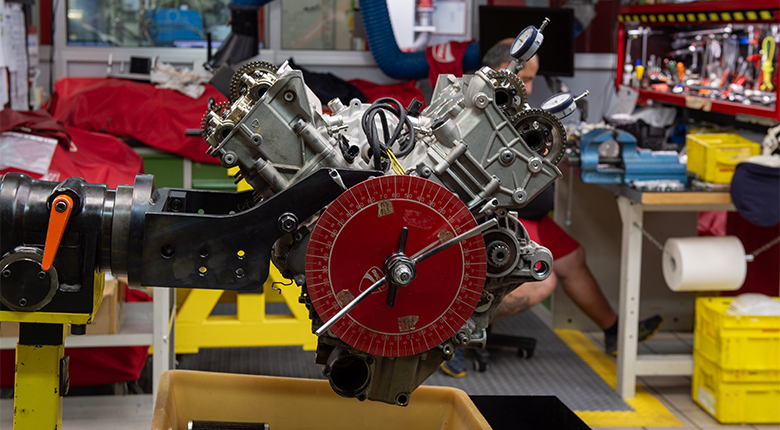

Ducati closely followed Motorrad's test, witnessing the final dismantling of the bike at the Ducati Stuttgart workshop. Ducati technicians analyzed every internal component together with the editorial staff, confirming:

Participation in the test was not a gamble: Ducati has always carried out internal endurance tests on its entire range. Several Multistrada V4s exceeded 100,000 km in these tests, and one in particular reached 200,000 km, showing the engine to be in excellent condition even after disassembly.

Some components were shared with suppliers for joint analysis, which confirmed the validity of the project and led to technical improvements, such as: